This article has been contributed by Ajay Gupta, Principal Consultant & Founder Perceptive Ideas Consulting Engineers Pvt. Ltd.

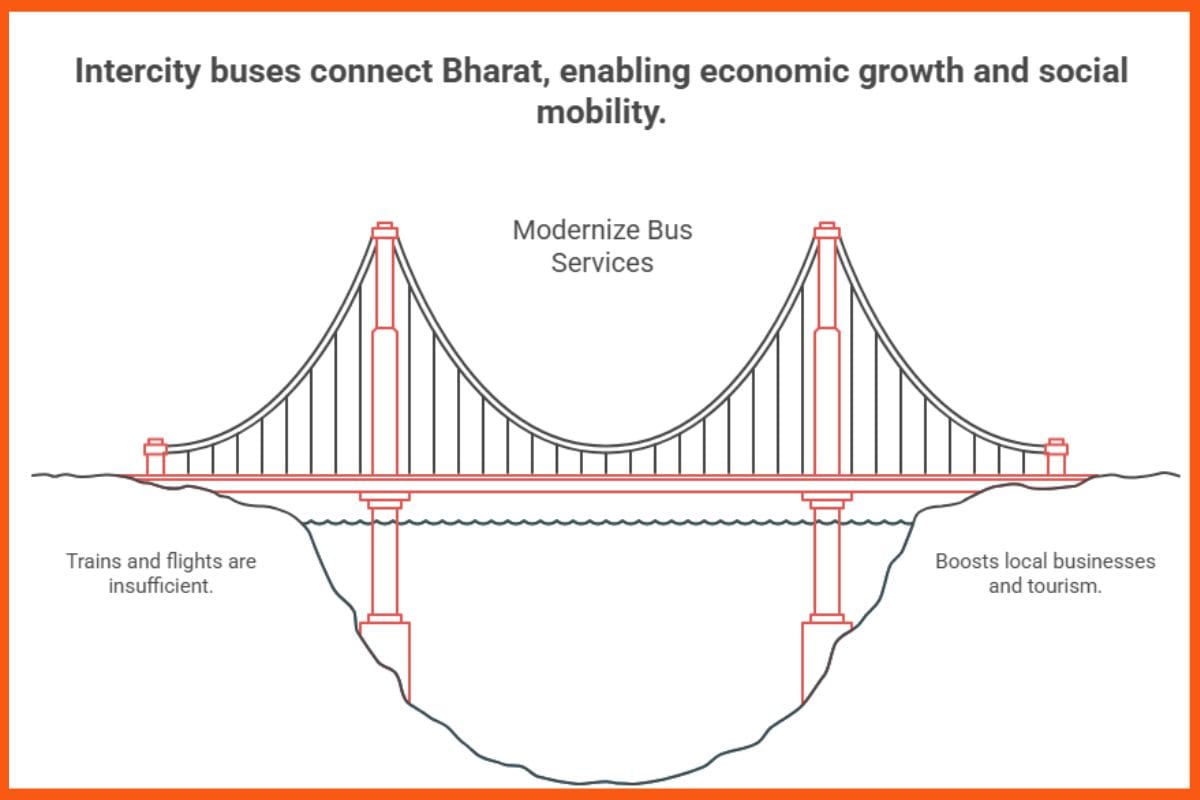

The escalating real estate costs are a multidimensional problem stemming from market dynamics, raw material prices, energy cost volatility, labour costs and design layout. They inadvertently affect developers’ profit margins as well as Construction Quality & Construction Timelines, causing a disruption in efforts of long-term sustainable urban development. The solution to this conundrum is quite simple. Structural designers have knowledge and techniques that can influence the simple game of demand and supply in the landscape of real estate.

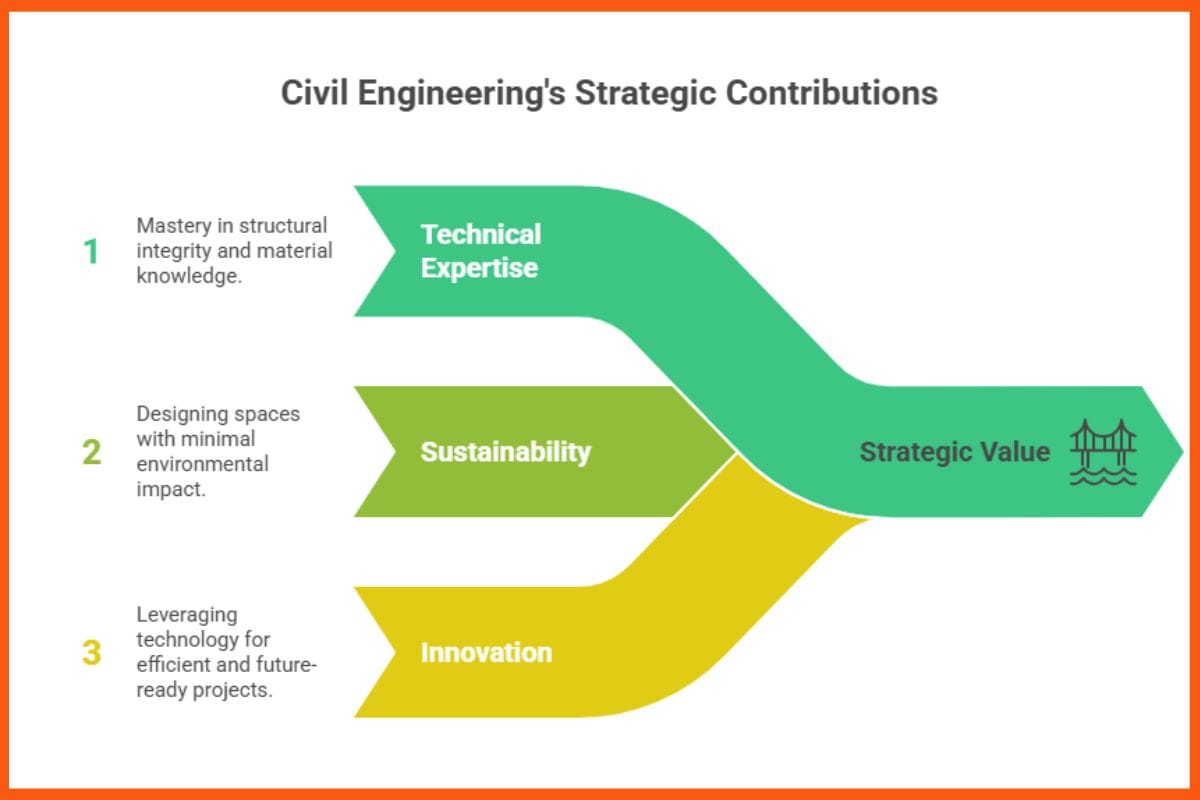

The structural design of the building directly influences the real estate cost, timelines and long-term durability (which in turn is itself a cost), and structural designers are the key to lowering construction costs. Responsible for designing the structural components of a building to guarantee safety and stability, structural designers have the power to determine the amount of raw materials and human resources that would be needed to build an infrastructure. At its simplest, their efficient design can become a cornerstone for profitability and growth amid the rising real estate costs, and that too without compromising the structural integrity of the building.

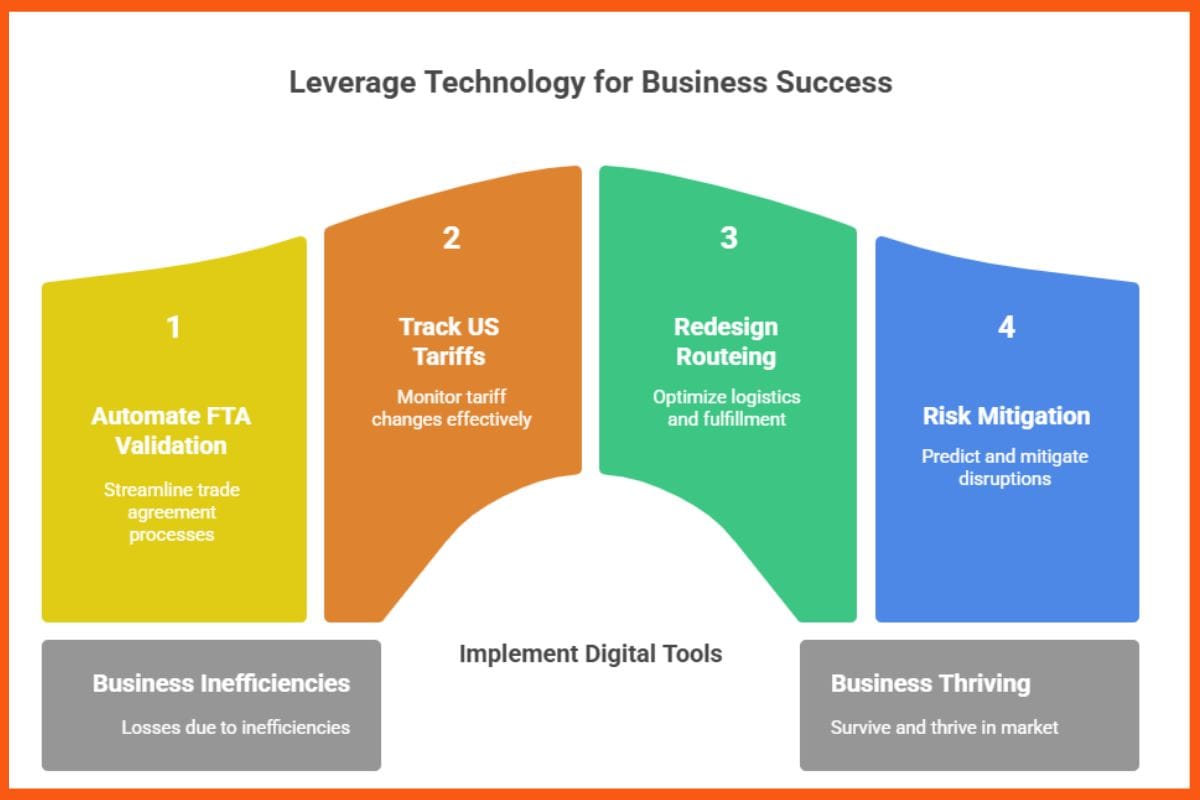

From integrating BIM (building information modelling) and sustainable construction techniques to using advanced structural analysis in designing columns, beams, foundations, and load-bearing walls, among others, an experienced structural designer can dramatically decrease the material requirements and labour costs of a construction project while creating resilient and sturdy foundations. Today, the challenge for them is to not just keep a building erect but also ensure the financials are taken care of to drive profitability and stability in the market.

Contributing to Value Engineering

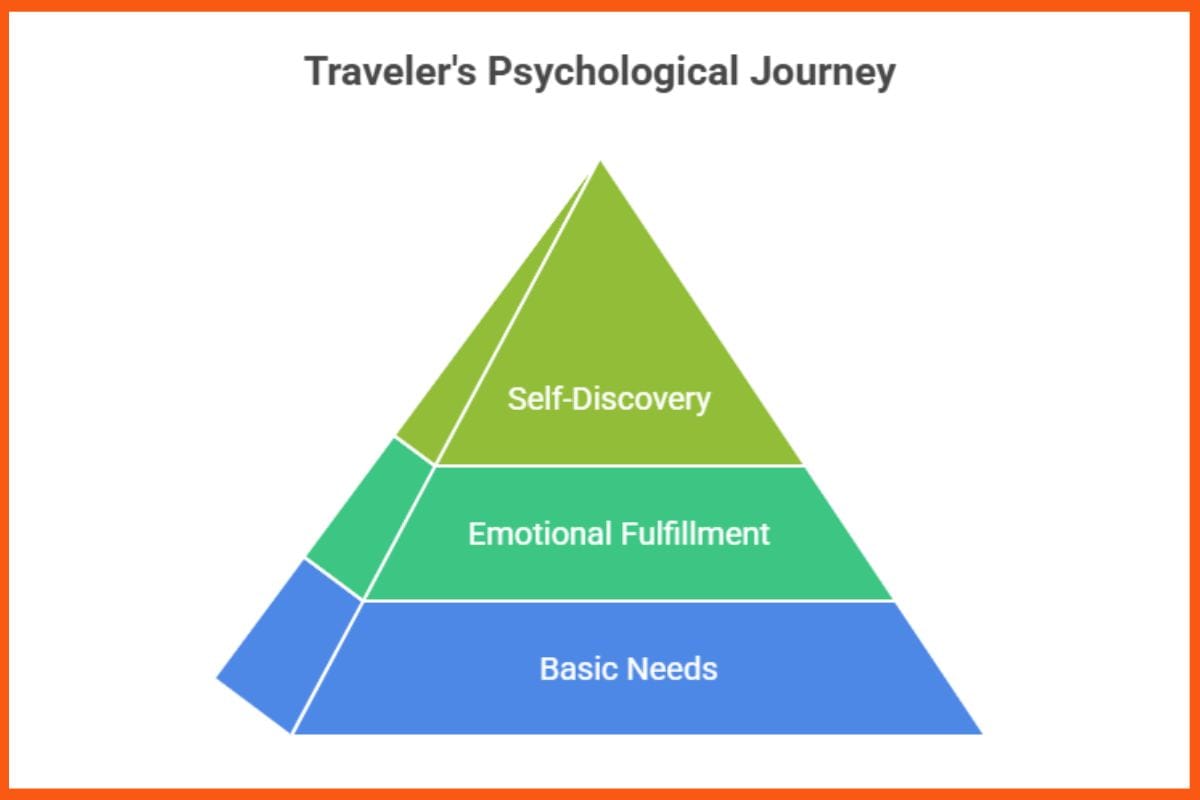

Value engineering has become a highly popular process for investors and developers, as it optimises the project to meet all requirements while ensuring a long life cycle and high endurance, which is the core of intelligent infrastructure that is created by structural engineers. Here are some ways in which they are reshaping the landscape of civil engineering.

Incredibly precise 3D modeling

Structural engineers can create 3D simulations of their vision through programs such as ETABS, STAAD PRO and SAP2000 with unmatched precision. These softwares allow for an incredibly advanced analysis of the design’s integrity and functionality against disasters and other environmental factors that affect a building’s life.

At the same time, the technology allows them to determine the right size and composition of elements, which in turn ensures that no wastage of materials occurs. It is an automated and highly accurate process that ensures reliability in every step, allowing for better planning and reducing vulnerability to market volatility. With Building Information Modelling, it also helps structural engineers identify mechanical, electrical and plumbing-related threats even before the construction process starts, which saves developers a huge amount in change orders or on-site rework.

Smart and Efficient Techniques

Prefabrication is a technique wherein the individual components of construction are created off-site and then assembled on-site through logistical power. This significantly saves the labour costs by reducing the time of construction as well as allows for greater precision in the making process. A method that uses BIM technology, it is great for bulk manufacturing and quality control besides cost efficiency. The key here lies in successful coordination and collaboration between Prefab Fabricators and Structural Engineers. The designers are in charge of creating a blueprint that is repeatable and suitable for a controlled factory environment to maximise the financial viability.

Doing More With Fewer Materials

Structural designers inspect every gram of raw material that is being used in making. Whether it is choosing a High-Strength Steel or Grades of Concrete, they take care of each specification, bearing in mind durability, environmental factors and the budget. The material choice can increase or decrease the required measurements of beams and foundations as well as columns, affecting the overall project costs. When designed with efficiency, the net profits can be maximised.

Post-tensioning in slabs is a popular technique that entails tensioned high-strength steel tendons being inserted in concrete, which makes the slabs thinner, reducing material usage. This saves money spent on cladding and curtain walls in large buildings by lowering the building’s height. Additionally, the number of columns needed to support the building also gets reduced, saving a considerable amount of space for dwellers.

Creating Cost-Effective Composites

Composite Construction: Combining materials to leverage their best properties is a key strategy. The most common example is steel-concrete composite decks. A profiled steel deck acts as permanent formwork and tensile reinforcement for a concrete slab. This system is incredibly fast to erect, reduces or eliminates traditional formwork, and creates a lightweight, strong floor system.

Value Engineering of Rebar

Shear walls, beams, columns, slabs, and foundations are just a few of the concrete components that are frequently reinforced with rebar. As a result, 20% or more of the cost of construction constitutes the expenditure for reinforcing concrete elements. Structural designers can greatly influence this by minimising the rebar diameters and shapes, which directly brings down the expenditure on fabrication, placement and labour. The 3D software helps in making detailed patterns that can affect the length of reabrs and reduce any wastage. Designers can use epoxy-coated or stainless steel rebars as replacements in environments which can make traditional rebars corrode soon, bringing down maintenance costs by a huge margin for homebuyers.

Choosing the Right Skeleton

Every site has specific requirements. The foundation size varies with every terrain and while moment frames can bring flexibility to the structure, they can also be material intensive. Thus, a structural engineer’s role in making the choice for the very skeleton of the system is of immense value to any project.

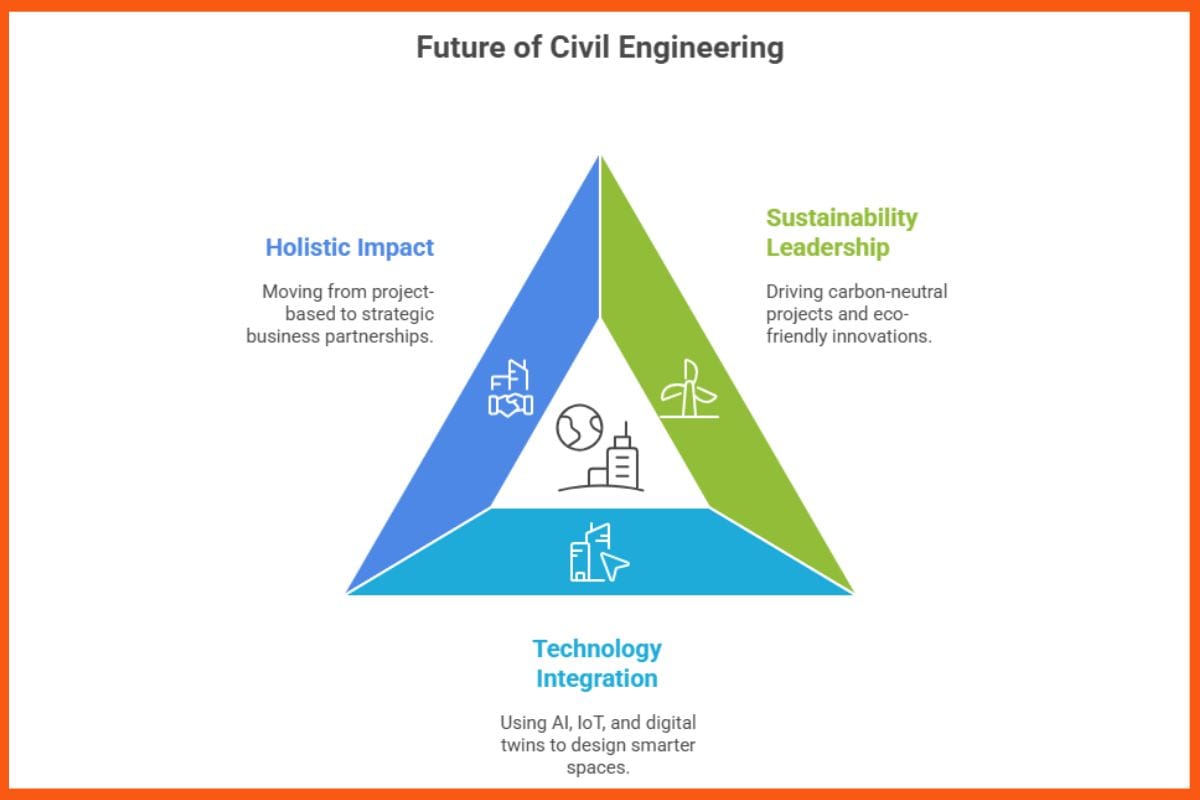

The Future Vision

Gone are the days when structural designers were mere technical consultants in development projects. Today, they are valuable partners for real estate, given that their design blueprints drastically affect the cost of construction without being involved in financial decision-making. They have the ability to optimise the raw material usage and speed up construction to tackle market volatility, directly decreasing the operational and capital expenditure. Proactive collaboration with them is thus non-negotiable to drive profitability in the real estate industry while also ensuring sustainability and safety.